Home » Dripmaster

With more than 40 years of experience in the development,manufacturing and marketing of control & monitoring instrumentation for the water market, Hoffmann & Hoffmann products are tailored towards increasing reliability of well operations, reducing well maintenance costs, and preventing well contamination.

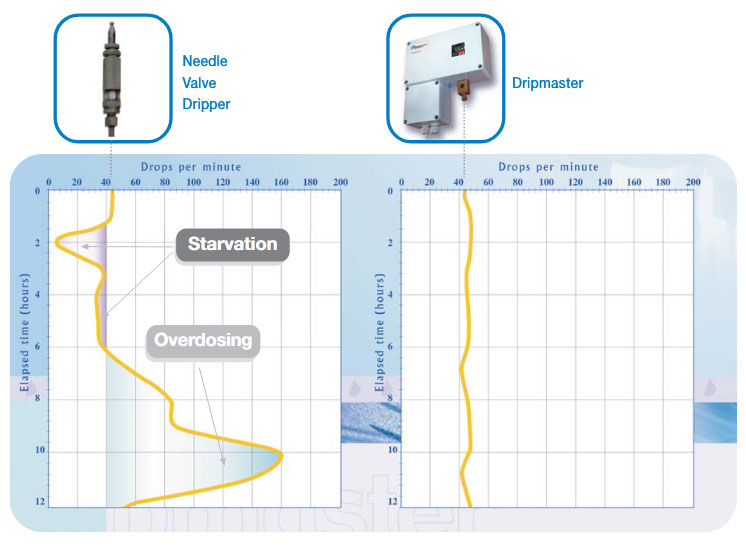

Optimal lineshaft lubrication is an essential issue when considering effective operation of the VTP. Bearing failure is a major cause of pump downtime. Approximately 50% of all bearing failures are due to improper lubrication. Lineshaft repairs are very costly and time consuming. Correct lubrication doses also reduce well contamination considerably.

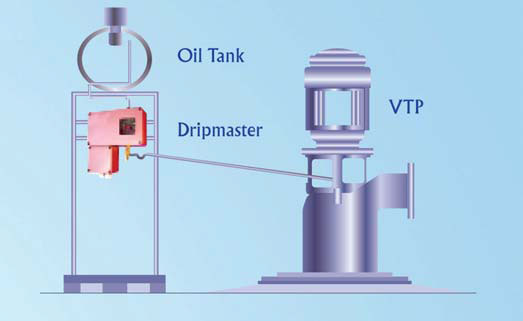

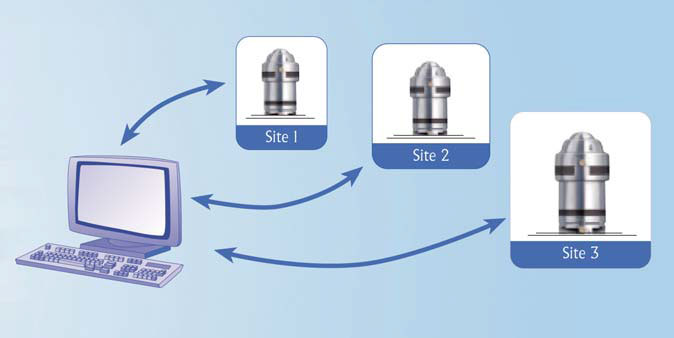

Is an active vertical lineshaft lubrication control and monitoring device. It automatically stabilizes the oil drip rate so as to comply to pump manufacturer’s requirements.

Installed below the oil tank and above the inlet to the lineshaft.

| Power requirements | 115 VAC, 10 VA or 24 V AC/DC 220 VAC, 10VA or 24V AC/DC |

| Normal mode preset drip rates | 20, 25, 30, 35, 40 dpm |

| Pre-lube mode drip rate | 2 dpm |

| Drip volume | 50 drops per 1 cc |

| PULSE relay contact | 35 VDC - 0.5 A |

| O.K. relay contact | 250 VAC - 10 A ACI; 110 VAC - 10 A ACI; 110 VDC - 0.3 A; 30 VDC - 10 A |

| L.L. relay contact | 125 VAC - 0.5 A 110 VDC - 0.2 A 24 VDC - 1 A |

| S.B. (Normal/Pre-lube mode control) | 24 V AC/DC |

| Duty Cycle | 60 secs count 6 secs freeze |

| Drip stabilizing tolerance | From x-1 to x+2 dpm (where x is the preselected drip rate) |

| Oil on/off solenoid | 24VDC 24VAC(optional) |

| Oil inlet/outlet | Male thread 1/4” BSP |

| Dimensions (whd) | 10.35x11.3x3.6 inches (263x287x91 mm) |

| Weight | 11 lbs (5 kg) |

All specifications shown in this brochure are subject to change